Share

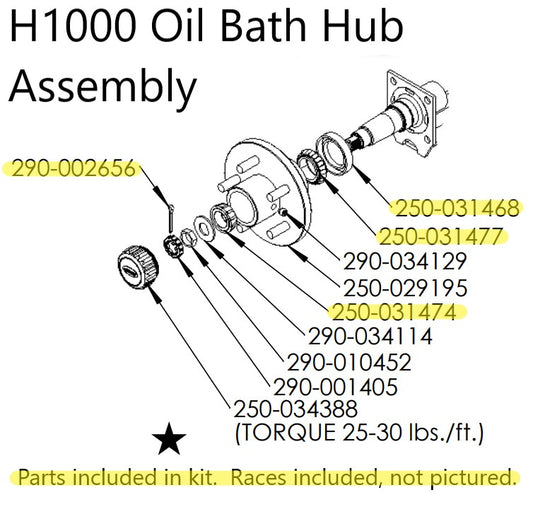

EZ Loader H1000 Oil Bath Hub Installation Information

To tighten the axle nut, tighten [pre-load] the axle nut to 30 foot pounds while turning the hub. Back the axle nut off. While backing off, do not disturb the hub. Then retighten the axle nut using a torque wrench to 18-24 inch lbs. [finger tight, do not over-tighten]. When the nut is tightened and positioned properly, the wheel should turn easily with no hub play when you rock the tire [side-to-side movement]. To replace the nut retainer, put it over the nut so that the cotter pin can be put in the spindle hole without loosening or tightening the nut. Rock the tire to check the hub play, check tightness, and loosen or tighten as needed. Put the cotter pin in the hole, bend the ends of the cotter pin and put on the oil bath cap and torque to 25-30 lbs/ft.

It is recommended to use Clarity 150 hub oil. With the Oil Bath Lubrication System, oil is applied through a hole located in the side of the hub. The hole is found by removing the Allen head oil drain plug from the side of the hub using a 3/16th Allen wrench. The oil is filled through the hole until it reaches the top of the EZ Loader logo on the sight glass of the oil bath cap.

*This information was referenced from the 2020 EZ Loader Adjustable Trailer Owner’s Manual. This document is for informational purpose and should not be used as instructions for trailer maintenance or repair. All trailer maintenance and repair should be completed by a qualified mechanic.